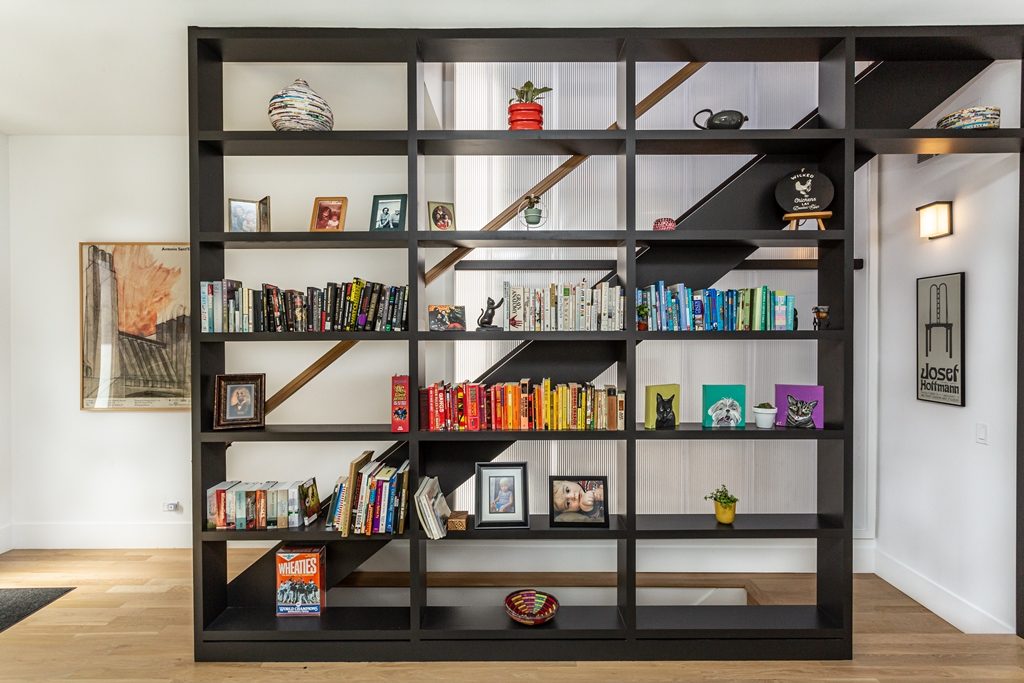

Years ago, architect Mike Ryan had a brief but positive experience with translucent polycarbonate glazing. It convinced him that this versatile material would be perfect for daylighting the stairway wall in his recently built home in Chicago.

Ryan designed a 10-foot-wide by 20-foot-high wall and filled it with Duo-Gard’s Series 3500 System, specifically engineered for vertical wall applications. “This wall is adjacent to a stairway, a place where typical windows would be hard to reach,” Ryan says. “Translucent polycarbonate was a way to bring in the natural light I wanted.”

And it was soft, diffused light without the harsh glare and heat gain of glass. It was also a significantly lower cost.

Architectural interest in translucent multiwall polycarbonate for residential applications isn’t widespread yet but it is increasing. “There’s a lack of awareness. I don’t think residential architects are very familiar with it,” says Ryan, AIA, senior architect at Chicago Roof Deck + Garden.

According to David Miller, president of Duo-Gard Industries, most residential architects and designers don’t understand and appreciate the advantages of the material, which has gained widespread use in commercial and industrial applications. Duo-Gard began designing and engineering systems for those applications more than 35 years ago.

“There’s a lot of education needed about the benefits of translucent daylighting for high performance, unique aesthetics, design flexibility and cost effectiveness,” Miller says. In fact, he says, Duo-Gard’s systems typically provide a 40 percent saving over glass, rivaling and often exceeding the performance.

Ryan says all these benefits were significant factors in his choice. His Duo-Gard Series 3500 System’s glazing, framed in clear anodized aluminum, provides 30 percent visible light transmission in a 40mm tongue-and-groove multiwall polycarbonate that achieves U-value 0.29 and R-value 3.57 for exceptional energy efficiency.

That energy efficiency can be enhanced with the addition of an advanced insulating aerogel called Lumira®. This dry silica particulate is filled with nano-pores that trap air to insulate up to R-8 in a single inch. It can be factory-filled to double a multiwall polycarbonate panel’s thermal value.

Miller says aesthetics play a major role in translucent daylighting for the residential market. Ryan chose an opal tint from among the contemporary color choices available today, ranging from bright blues to subtle greens and sophisticated charcoals. This year, Duo-Gard added matte finish panels as well as multi-color options which enable a designer to choose one color for a panel’s interior and another for the exterior.

One of multiwall polycarbonate’s most appealing features is its design and engineering versatility, according to David Miller. “It’s virtually shatterproof with 200 times the impact strength of glass at only 1/6th the weight,” he points out, “which means it can accommodate designs with wider spans and lighter supports.” It also cold-forms easily so designers can create dramatic curved walls and accents.

“Because polycarbonate systems are dry-glazed, they require special framing,” he adds. “Those unfamiliar with the material assume it can be framed like glass, thus creating performance problems. Polycarbonate expands and contracts, requiring framing that allows it to “float” in the frame.” Duo-Gard’s structural systems are specifically engineered for polycarbonate glazings.

Miller says residential architects and designers should look seriously at the material, and not just for window walls. He cites canopies, pergolas, pool covers and shade structures as examples of the possibilities.

But what about sacrificing views of the great outdoors? A challenge easily addressed, Miller says: “Our systems can be engineered to include visibility sections to suit the designer.”

Mike Ryan’s family took up residence in March 2019, and he says the translucent polycarbonate wall was “a great option” for the new home.

Photography by Ben Gonzales